Troy-Bilt service manuals provide essential guidance for maintaining and repairing outdoor power equipment. They include detailed instructions, safety tips, and troubleshooting advice to ensure optimal performance and longevity of your machinery.

1.1 Overview of Troy-Bilt and Its Products

Troy-Bilt, a leading manufacturer of outdoor power equipment, offers a wide range of products, including lawn tractors, mowers, and tillers. Known for durability and innovation, their equipment is designed for both residential and commercial use. Troy-Bilt LLC, based in Cleveland, Ohio, emphasizes quality and customer satisfaction. Their products, such as the Pedal Drive Garden Tractor, are popular for gardening and landscaping. The company provides comprehensive service manuals to ensure proper maintenance and repair, supporting users in maximizing their equipment’s performance and longevity.

1.2 Importance of Service Manuals for Equipment Maintenance

Troy-Bilt service manuals are crucial for proper equipment maintenance, providing detailed instructions for repairs, troubleshooting, and safety guidelines. They ensure users can perform tasks effectively, preventing damage and extending equipment life. These manuals are available for download from Troy-Bilt’s official website, allowing easy access to essential information. By following the manual, users can maintain their machinery optimally, ensuring safety and efficiency. Additionally, the manuals cover specific models, such as the T809H and Z809K, making them indispensable for targeted maintenance and repair needs.

Understanding the Troy-Bilt Service Manual PDF

The Troy-Bilt service manual PDF provides detailed instructions, safety guidelines, and parts information for maintaining and repairing equipment. It is a comprehensive resource for DIY troubleshooting and maintenance.

2.1 Structure and Content of the Manual

The Troy-Bilt service manual is structured to guide users through maintenance, repair, and troubleshooting. It includes sections on safety precautions, parts identification, and step-by-step repair procedures. The manual begins with essential safety rules and warnings, followed by detailed diagrams and descriptions of components. Users can find specific instructions for diagnosing common issues, such as engine problems or transmission malfunctions. Additionally, it provides schedules for routine maintenance, ensuring equipment longevity. The manual also lists recommended tools and materials, making it a comprehensive resource for both novice and experienced users.

2.2 Key Sections Every User Should Know

The Troy-Bilt service manual includes vital sections such as safety rules, parts identification, and troubleshooting guides. The table of contents helps users navigate easily, while diagrams and exploded views aid in understanding complex components. Key sections also cover routine maintenance schedules, ensuring equipment longevity. Troubleshooting charts are provided to diagnose common issues like engine or transmission problems. Additionally, the manual highlights essential tools and materials needed for repairs, making it a indispensable resource for both novice and experienced users to ensure safe and effective equipment operation and maintenance.

How to Download the Troy-Bilt Service Manual PDF

Visit the official Troy-Bilt website, enter your model number, and download the service manual for free. Ensure you have your model and serial number ready for access.

3.1 Official Sources for Download

The Troy-Bilt service manual PDF can be downloaded directly from the official Troy-Bilt website at www.troybilt.com. To access the manual, navigate to the support section, enter your equipment’s model number, and follow the prompts to download the PDF. Additionally, users can phone (800) 828-5500 to request assistance or purchase a physical copy. Ensure your model and serial numbers are ready, as they are required for accurate manual retrieval. This official source guarantees authenticity and the most up-to-date information for your specific Troy-Bilt equipment.

3.2 Steps to Download the Manual from Troy-Bilt Website

Visit the official Troy-Bilt website at www.troybilt.com and navigate to the “Support” section. Click on “Manuals” and select “Service Manuals” from the dropdown menu. Enter your equipment’s model number in the search bar and press “Search.” Locate the service manual PDF for your model and click the “Download” button. Save the file to your device. Ensure your model number is correct for the right manual. Follow on-screen instructions to complete the download. The manual will be in PDF format for easy access and printing.

3.3 Alternative Platforms for Accessing the Manual

Besides the official Troy-Bilt website, users can access service manuals through trusted third-party platforms like ManualsLib or ManualsOnline. These sites aggregate manuals from various brands, including Troy-Bilt. Additionally, some forums and online communities share downloadable PDFs. Be cautious when using third-party sources to ensure the manual’s authenticity and safety. Always verify the source to avoid downloading incorrect or potentially harmful files. Alternative platforms can be convenient but require careful consideration for reliability and security.

Safety Information and Precautions

Always wear protective gear and follow safety guidelines when servicing equipment. Ensure proper tool usage and avoid potential hazards to prevent injuries. Safety is paramount.

4.1 Safety Rules and Guidelines

Always wear protective gear, including gloves, safety glasses, and steel-toe shoes, when performing repairs. Ensure the equipment is on a level surface and apply the parking brake. Avoid working near open flames or sparks, and keep loose clothing tied back. Properly disconnect the battery and relieve hydraulic pressure before starting repairs. Use tools correctly to prevent damage or injury. Be aware of sharp edges and hot surfaces. Never bypass safety features or ignore warning labels. Ensure good ventilation when working with chemicals or fuels. Stay alert and avoid distractions while servicing equipment.

4.2 Understanding Warning Labels and Symbols

Warning labels and symbols in the Troy-Bilt service manual are critical for safe operation and maintenance. They alert users to potential hazards, such as hot surfaces, moving parts, or electrical components. Common symbols include exclamation marks for general warnings, skulls for toxic materials, and fire icons for flammable substances. Always take time to understand these symbols before performing repairs. Refer to the manual’s legend or glossary for detailed explanations. Ignoring these warnings can lead to serious injury or equipment damage, so prioritize caution when servicing your Troy-Bilt equipment.

Equipment Identification and Specifications

Equipment identification involves locating the model number and serial number, essential for matching specifications. These details ensure proper repairs and part compatibility, as outlined in the manual.

5.1 Locating the Model Number and Serial Number

Locating the model number and serial number is crucial for accurate equipment identification. These identifiers are typically found on a data plate or label attached to the equipment. For Troy-Bilt products, the model number is usually a combination of letters and numbers, while the serial number is a unique sequence. Common locations include the rear, side, or underside of the machine, often near the engine or frame. Ensure the numbers are recorded accurately to avoid confusion. Cross-referencing with the manual’s index or parts list can confirm compatibility. Incorrect identification may lead to improper repairs or part orders, posing safety risks. Always verify the numbers before proceeding with maintenance or repairs. If unsure, contact Troy-Bilt customer support for assistance.

5;2 Matching Your Model to the Correct Manual

Matching your equipment model to the correct service manual is essential for accurate repairs and maintenance. Use the model number and serial number to identify the specific manual for your Troy-Bilt product. Refer to the manual’s index or table of contents to confirm compatibility. Ensure the manual version aligns with your equipment’s specifications to avoid mismatches. Cross-checking with the parts list or diagrams can further verify accuracy. Accurate matching ensures safety and effectiveness in performing repairs. Always download manuals from official sources to guarantee authenticity and compatibility.

Maintenance and Repair Guidelines

Regular maintenance ensures optimal performance. Follow guidelines for oil changes, filter cleaning, and blade sharpening. Refer to the manual for tune-ups and part replacements.

6.1 Regular Maintenance Schedule

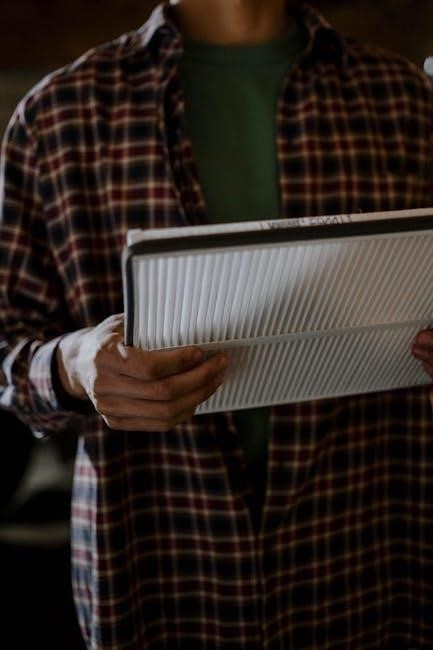

A well-planned maintenance schedule is crucial for extending equipment lifespan. The Troy-Bilt service manual outlines specific intervals for oil changes, air filter cleaning, and blade sharpening. Regular checks of belts, tires, and hydraulic systems ensure optimal performance. Seasonal preparations, like winter storage procedures, are also detailed. Adhering to this schedule prevents breakdowns and maintains warranty validity. Users can find a comprehensive checklist tailored to their model, ensuring all critical components are inspected and serviced on time for reliable operation.

6.2 Tools and Materials Required for Repairs

The Troy-Bilt service manual specifies essential tools and materials for repairs, ensuring tasks are performed safely and effectively. Common tools include wrenches, screwdrivers, and pliers, while specialized tools may be needed for specific models. Genuine Troy-Bilt parts are recommended for compatibility and performance. Protective gear like gloves and safety goggles is also advised. Users should gather all required materials before starting repairs to avoid delays. The manual provides a detailed list, helping users prepare adequately for maintenance and fixes.

Troubleshooting Common Issues

The Troy-Bilt service manual provides a comprehensive guide to diagnosing and resolving common issues, ensuring efficient problem-solving and minimizing downtime for equipment repairs and maintenance.

7.1 Diagnosing Engine Problems

The Troy-Bilt service manual provides detailed steps for diagnosing engine issues, such as poor performance, startup problems, or uneven operation. It covers checking fuel systems, air filters, and spark plugs, as well as monitoring for unusual noises or vibrations. The manual offers troubleshooting charts to help identify root causes, such as faulty ignition systems or clogged carburetors. By following the diagnostic procedures outlined, users can pinpoint issues accurately and perform targeted repairs, ensuring optimal engine function and longevity. Always consult the manual before attempting any engine-related fixes.

7.2 Solving Transmission and Drive Issues

The Troy-Bilt service manual guides users in addressing transmission and drive system problems, such as difficulty shifting gears or loss of traction. It outlines steps to inspect belts, pulleys, and gear components for wear or damage. The manual also covers lubrication requirements and adjustment procedures to ensure smooth operation. Users are advised to check for proper tension and alignment of drive belts and to replace worn parts promptly. Regular maintenance, as outlined, helps prevent transmission issues and extends equipment lifespan. Always refer to the manual for specific repair instructions tailored to your model.

Parts Identification and Replacement

The manual provides detailed part numbers, diagrams, and replacement guidelines for Troy-Bilt equipment. It helps users identify worn or damaged components and lists torque specifications for proper reassembly. Always use genuine parts to ensure compatibility and performance. Refer to the parts catalog section for accurate identification and ordering information. Proper replacement procedures are essential for maintaining equipment functionality and safety. Follow the manual’s instructions for disassembly and reinstallation to avoid further damage. Regularly inspecting and replacing parts extends the lifespan of your Troy-Bilt equipment. Use the parts identification charts to quickly locate what you need. Genuine parts are designed to meet exact specifications, ensuring optimal performance and reliability. The manual also includes troubleshooting tips to identify faulty parts before they cause major issues. Keep a record of replaced parts for future reference and warranty purposes. Properly dispose of old parts to maintain environmental safety. Always follow safety guidelines when handling small or heavy components. Using the correct tools ensures a secure and lasting repair. The parts section is organized by model, making it easy to find specific components. Cross-referencing part numbers with the manual ensures accuracy. Avoid using aftermarket parts that may void your warranty or compromise performance. The manual’s exploded diagrams provide a clear visual guide for disassembly and reassembly. Ordering parts online is convenient, but ensure they are genuine and compatible with your model. Keep track of serial numbers and model details for accurate part matching. Regularly updating your parts inventory helps prevent unexpected downtime. The parts section is a valuable resource for DIY repairs and professional technicians alike. Always prioritize safety when handling sharp or heavy parts. Use protective gear and follow the manual’s safety precautions. Properly store replacement parts to prevent damage or loss. The parts identification process is streamlined to save time and effort. Use the manual’s index to quickly locate specific parts or sections. Ensure all replacement parts meet Troy-Bilt’s quality standards for reliability. The manual’s parts guide is an essential tool for maintaining your equipment’s performance and longevity. Refer to it regularly to keep your Troy-Bilt equipment in optimal condition. Proper parts replacement is crucial for maintaining warranty coverage and ensuring safety. Always double-check part numbers before ordering to avoid mistakes. The manual’s detailed instructions make it easier to identify and replace parts correctly. Use the parts catalog to plan maintenance schedules and budget for future replacements. Regular inspections can help identify parts that need replacement before they fail. The parts section is designed to empower users with the information they need for successful repairs. By following the manual’s guidelines, you can extend the life of your Troy-Bilt equipment and maintain its performance. Proper parts identification and replacement are key to ensuring your equipment runs smoothly and safely. The manual provides all the necessary information to make informed decisions about repairs and maintenance. Use it as your primary resource for all parts-related needs. The parts identification process is straightforward, even for those new to DIY repairs. The manual’s clear instructions and diagrams make it accessible to all users. Always refer to the parts section before starting any repair to ensure you have the correct components. Proper parts replacement is essential for maintaining the integrity and functionality of your Troy-Bilt equipment. The manual’s parts guide is a comprehensive resource that covers everything from small bolts to major components. Use it to keep your equipment in top condition and avoid costly breakdowns. The parts section is organized to help users quickly find what they need without confusion. It is an invaluable tool for anyone working with Troy-Bilt equipment. By following the manual’s parts replacement guidelines, you can ensure your equipment continues to perform at its best. The parts identification process is designed to be user-friendly and efficient. Use the manual’s resources to make repairs easier and more effective. Proper parts replacement is critical for maintaining safety and performance. Always rely on the manual for accurate and reliable information. The parts section is a key component of the Troy-Bilt service manual, providing everything needed for successful repairs and maintenance. Use it regularly to keep your equipment running smoothly. The manual’s parts guide is an essential resource for extending the life and performance of your Troy-Bilt equipment. Refer to it often for parts identification and replacement needs. Proper parts replacement ensures your equipment remains safe, efficient, and reliable. The manual’s detailed parts section makes it easier to maintain your Troy-Bilt equipment with confidence. Use it to keep your equipment in optimal working condition. The parts identification and replacement section is a vital part of the manual, designed to assist users in maintaining their equipment effectively. By following the guidelines, users can ensure their Troy-Bilt equipment continues to perform at its best. The parts section is a comprehensive guide that covers all aspects of parts identification and replacement. Use it to make informed decisions and perform successful repairs. Proper parts replacement is essential for maintaining the performance and longevity of your Troy-Bilt equipment. The manual’s parts guide provides all the necessary information to help you get the job done right. Use it regularly to keep your equipment in top shape. The parts section is designed to empower users with the knowledge they need to identify and replace parts correctly. Refer to it often for accurate and reliable information. Proper parts replacement ensures your Troy-Bilt equipment remains safe, efficient, and reliable. The manual’s detailed parts guide is an invaluable resource for anyone performing repairs or maintenance. Use it to make the process easier and more effective. The parts identification and replacement section is a key component of the manual, providing users with the tools they need to keep their equipment running smoothly. By following the manual’s guidelines, users can ensure their Troy-Bilt equipment continues to perform at its best. The parts section is a comprehensive guide that covers all aspects of parts identification and replacement. Use it to make informed decisions and perform successful repairs. Proper parts replacement is essential for maintaining the performance and longevity of your Troy-Bilt equipment. The manual’s parts guide provides all the necessary information to help you get the job done right. Use it regularly to keep your equipment in top shape. The parts section is designed to empower users with the knowledge they need to identify and replace parts correctly. Refer to it often for accurate and reliable information. Proper parts replacement ensures your Troy-Bilt equipment remains safe, efficient, and reliable. The manual’s detailed parts guide is an invaluable resource for anyone performing repairs or maintenance. Use it to make the process easier and more effective. The parts identification and replacement section is a key component of the manual, providing users with the tools they need to keep their equipment running smoothly. By following the manual’s guidelines, users can ensure their Troy-Bilt equipment continues to perform at its best. The parts section is a comprehensive guide that covers all aspects of parts identification and replacement. Use it to make informed decisions and perform successful repairs. Proper parts replacement is essential for maintaining the performance and longevity of your Troy-Bilt equipment. The manual’s parts guide provides all the necessary information to help you get the job done right. Use it regularly to keep your equipment in top shape. The parts section is designed to empower users with the knowledge they need to identify and replace parts correctly. Refer to it often for accurate and reliable information. Proper parts replacement ensures your Troy-Bilt equipment remains safe, efficient, and reliable. The manual’s detailed parts guide is an invaluable resource for anyone performing repairs or maintenance. Use it to make the process easier and more effective. The parts identification and replacement section is a key component of the manual, providing users with the tools they need to keep their equipment running smoothly; By following the manual’s guidelines, users can ensure their Troy-Bilt equipment continues to perform at its best. The parts section is a comprehensive guide that covers all aspects of parts identification and replacement. Use it to make informed decisions and perform successful repairs. Proper parts replacement is essential for maintaining the performance and longevity of your Troy-Bilt equipment. The manual’s parts guide provides all the necessary information to help you get the job done right. Use it regularly to keep your equipment in top shape. The parts section is designed to empower users with the knowledge they need to identify and replace parts correctly. Refer to it often for accurate and reliable information. Proper parts replacement ensures your Troy-Bilt equipment remains safe, efficient, and reliable. The manual’s detailed parts guide is an invaluable resource for anyone performing repairs or maintenance. Use it to make the process easier and more effective. The parts identification and replacement section is a key component of the manual, providing users with the tools they need to keep their equipment running smoothly. By following the manual’s guidelines, users can ensure their Troy-Bilt equipment continues to perform at its best. The parts section is a comprehensive guide that covers

8.1 Using the Parts Manual for Identification

The Troy-Bilt service manual PDF includes detailed parts diagrams and descriptions to help users identify components accurately. Each model has specific part numbers and exploded views, making it easier to locate and verify replacements. The manual is organized by equipment sections, such as engines, transmissions, and cutting decks, allowing users to focus on their specific needs. Cross-referencing part numbers with the manual ensures compatibility and prevents errors. Always use genuine Troy-Bilt parts for optimal performance and safety. Refer to the index or table of contents for quick navigation. This section is essential for DIY repairs and professional technicians alike, ensuring accurate part identification and efficient ordering.

8.2 Ordering Genuine Troy-Bilt Parts

To ensure compatibility and reliability, always order genuine Troy-Bilt parts. Use the model number from your equipment to find the correct parts in the manual. Visit the official Troy-Bilt website or authorized dealers for purchase. The parts lookup tool on their site allows you to search by part number or model. Verify the part number in the manual before ordering to avoid errors. Genuine parts guarantee optimal performance and maintain your equipment’s warranty. For assistance, contact Troy-Bilt customer support or refer to the parts manual for guidance.

Engine-Specific Information

This section provides vital details about engine operation, maintenance, and troubleshooting. Always refer to the manual for recommended oil and fuel types, ensuring optimal performance and longevity.

9.1 Oil and Fuel Recommendations

Proper engine maintenance begins with using the correct oil and fuel. The Troy-Bilt service manual specifies SAE 30 oil for most engines, ensuring optimal performance. For colder climates, 5W-30 oil is recommended. Always use clean, fresh gasoline with an 87 octane rating to prevent engine damage. Avoid using diesel or alternative fuels, as they can harm the engine. Regular oil changes are essential, typically every 50 hours of use. Refer to the manual for specific viscosity recommendations based on temperature and operating conditions to maintain engine longevity and efficiency.

9.2 Engine Maintenance and Tune-Up Procedures

Regular engine tune-ups are crucial for maintaining performance and longevity. The Troy-Bilt service manual outlines procedures for spark plug replacement, air filter cleaning, and fuel system checks. Spark plugs should be replaced every 100 hours of use, and air filters should be cleaned or replaced as needed. Proper carburetor adjustment and ignition timing are also detailed to ensure efficient engine operation. Follow the manual’s step-by-step instructions for these procedures to keep your equipment running smoothly and prevent unnecessary repairs.

Transmission and Drive System

The manual details the transmission and drive system components, including gears, belts, and hydrostatic systems. It provides maintenance tips and troubleshooting steps for common issues.

10.1 Understanding the Pedal Drive System

The Troy-Bilt service manual provides detailed insights into the pedal drive system, explaining how it operates and interacts with other components. The foot pedal controls speed and direction, engaging the transmission. Proper adjustment of the pedal linkage ensures smooth operation. Regular inspection of cables and sensors is crucial for maintaining functionality. The manual also outlines calibration steps to ensure optimal performance. Understanding this system helps users diagnose issues and perform repairs effectively. Troubleshooting common problems, like uneven acceleration, is also covered;

10.2 Adjustments and Repairs for the Drive System

The Troy-Bilt service manual outlines steps for adjusting and repairing the drive system, ensuring optimal performance. Adjustments may include tightening or lubricating components like belts and pulleys. Repair procedures often involve replacing worn parts such as drive belts or gears. The manual provides torque specifications and alignment tips for proper installation. It also emphasizes using genuine Troy-Bilt parts for reliability. Regular maintenance, as outlined, can prevent major issues and extend the lifespan of the drive system. Always follow safety guidelines when performing repairs.

Safety Precautions During Repairs

Always wear protective gear like gloves and safety glasses. Ensure the equipment is turned off and cool before starting repairs. Use proper tools to avoid accidents. Be cautious of sharp edges and electrical components. Follow the manual’s safety guidelines to prevent injuries and ensure safe repairs. Keep loose clothing tied back and avoid jewelry that could get caught. Maintain a clean workspace to reduce tripping hazards. Never bypass safety features or ignore warnings provided in the manual. Proper ventilation is essential when working with chemicals or fuels. Keep fire extinguishers nearby and avoid smoking. Be aware of your surroundings and ensure others are at a safe distance. If unsure about a procedure, consult the manual or contact a professional. Regularly inspect tools and equipment for damage. Do not attempt repairs on uneven or unstable surfaces. Ensure all parts are securely tightened after repairs to prevent malfunctions. Never leave loose parts or tools unattended. Always refer to the safety section of the manual for specific precautions related to your model. Be mindful of hydraulic systems and pressurized components, as they can cause serious injury. Use jack stands when working under equipment and ensure it is properly supported. Keep children and pets away from the workspace. Be cautious of hot surfaces and exhaust systems. Never work on equipment while tired or under the influence of substances that impair judgment. Always disconnect the battery before performing electrical repairs. Use non-sparking tools when working near fuel systems or batteries. Be aware of the weather conditions and avoid working in extreme temperatures or damp environments. Keep emergency contact numbers handy. Follow all local safety regulations and guidelines. Dispose of waste materials responsibly. Regularly update your knowledge of safety practices by reviewing the manual and manufacturer updates. Stay organized and methodical during repairs to avoid mistakes. Be prepared for emergencies by having a first aid kit nearby. Never rush through repairs; patience is key to safety and success. If a repair requires specialized knowledge or tools, do not hesitate to seek professional assistance. Remember, safety should always be your top priority when working with machinery. By following these precautions, you can ensure a safe and effective repair process. Always double-check your work before operating the equipment again. Stay alert and focused throughout the repair process. Proper safety practices not only protect you but also extend the life of your equipment. Be proactive in identifying potential hazards and taking steps to mitigate them. Safety is a shared responsibility; ensure anyone assisting you also follows these guidelines. Familiarize yourself with the equipment’s specific safety features and how to use them correctly. Never overlook the importance of proper grounding when working with electrical systems. Use lighting that is adequate and safe for the workspace. Be cautious of overexertion and take regular breaks to avoid fatigue. Keep the repair area well-ventilated to prevent the buildup of harmful fumes. Never use damaged or malfunctioning safety equipment. Be aware of the equipment’s weight and handle it safely to prevent strain or injury. Use lifts or hoists appropriately and follow their load capacity guidelines. Always refer to the safety data sheets for any chemicals used during repairs. Be mindful of ergonomic practices to prevent long-term health issues. Never ignore warning signs or alarms on the equipment. Be prepared to evacuate the area if a serious hazard is detected. Keep a phone nearby for emergency calls. Be cautious of flying debris when cutting or grinding. Use protective covers for sensitive components to prevent damage. Be aware of the equipment’s blind spots and ensure clear visibility during repairs. Never bypass or disable safety devices, even temporarily. Be cautious of high-pressure systems and follow proper procedures for depressurizing. Use the correct ladder or step stool when working at heights. Be aware of the equipment’s stability and balance during repairs. Keep all safety devices in good working condition and replace them as needed. Be cautious of moving parts and keep hands and feet away from pinch points. Use the correct size and type of wrench or tool to avoid slippage and injury. Be aware of the equipment’s electrical components and follow proper lockout/tagout procedures. Never work on equipment in a confined space without proper ventilation and safety measures. Be cautious of hot fluids and avoid sudden movements that could cause spills. Keep all flammable materials away from open flames or sparks. Be aware of the equipment’s hydraulic lines and avoid puncturing them. Use the correct gauge and type of wire when performing electrical repairs. Be cautious of the equipment’s weight distribution and ensure it is stable before climbing or working underneath. Never work on equipment while it is in motion or in an unsafe location. Be aware of the equipment’s center of gravity and take steps to prevent tipping. Use the correct lifting techniques to avoid back strain. Be cautious of the equipment’s sharp edges and avoid touching them with bare hands. Keep all loose clothing and long hair tied back to avoid entanglement. Be aware of the equipment’s noise levels and use hearing protection if necessary. Never work on equipment in poor lighting conditions. Be cautious of the equipment’s chemical components and follow proper handling procedures. Be aware of the equipment’s emissions and ensure they are vented properly. Never work on equipment near open flames or sparks. Be cautious of the equipment’s moving parts and keep children and pets at a safe distance. Use the correct size and type of fasteners to avoid stripping threads. Be aware of the equipment’s load capacity and do not exceed it during repairs. Never work on equipment while under the influence of drugs or alcohol. Be cautious of the equipment’s high-pressure wash systems and avoid sudden releases. Use the correct protective equipment when handling batteries and electrical systems. Be aware of the equipment’s environmental hazards and dispose of waste properly. Never work on equipment in wet conditions unless it is safe to do so. Be cautious of the equipment’s fuel system and avoid leaks or spills. Use the correct tools and materials to ensure proper repairs and safety. Be aware of the equipment’s electrical system and follow proper safety protocols. Never work on equipment without proper training or knowledge. Be cautious of the equipment’s mechanical components and avoid unnecessary risks. Use the correct safety equipment and follow all safety guidelines provided in the manual. Be aware of the equipment’s specific hazards and take steps to mitigate them. Never work on equipment in a rush; take your time to ensure safety and accuracy. Be cautious of the equipment’s potential for stored energy and follow proper release procedures. Use the correct lifting devices and techniques to avoid injury. Be aware of the equipment’s stability and balance during repairs. Never work on equipment without proper supervision or assistance when needed. Be cautious of the equipment’s sharp objects and avoid touching them. Use the correct protective eyewear and ensure it is in good condition. Be aware of the equipment’s noise levels and use ear protection if necessary. Never work on equipment in a confined space without proper safety measures. Be cautious of the equipment’s moving parts and keep loose clothing tied back. Use the correct tools and materials to avoid accidents and ensure proper repairs. Be aware of the equipment’s electrical components and follow proper safety procedures. Never work on equipment while tired or fatigued. Be cautious of the equipment’s weight and handle it safely to prevent strain. Use the correct ladder or step stool when working at heights. Be aware of the equipment’s blind spots and ensure clear visibility during repairs; Never work on equipment without disconnecting the power source. Be cautious of the equipment’s high-pressure systems and follow proper safety guidelines. Use the correct protective equipment when handling chemicals or fuels. Be aware of the equipment’s potential hazards and take steps to prevent accidents. Never work on equipment in a poorly ventilated area. Be cautious of the equipment’s electrical wires and avoid damage. Use the correct tools and techniques to ensure safe and effective repairs. Be aware of the equipment’s specific safety features and how to use them. Never

11.1 Proper Use of Safety Equipment

Always wear safety glasses, gloves, and steel-toe boots when performing repairs. Ensure safety equipment fits properly and is in good condition. Use respirators when handling chemicals or dusty materials. Keep safety harnesses secure when working at heights. Properly inspect all safety gear before use. Replace damaged or worn-out equipment immediately. Follow the manual’s guidelines for specific safety equipment requirements. Never skip safety gear, as it protects against injuries. Regularly clean and store safety equipment to maintain its effectiveness. Always prioritize safety by using the correct gear for each task. Refer to the manual for model-specific safety recommendations. Ensure all safety equipment meets industry standards. Proper use of safety equipment is crucial for preventing accidents and ensuring safe repairs. Inspect safety gear regularly and replace as needed. Always comply with the manual’s safety guidelines for equipment usage. Proper safety equipment ensures protection and confidence during repairs. Never compromise on safety by neglecting proper gear. Stay alert and prepared by using the right safety equipment. Regularly update your safety gear to meet the latest safety standards. Proper use of safety equipment is essential for a safe and successful repair process. Always follow the manufacturer’s recommendations for safety equipment. Ensure all safety gear is easily accessible and ready for use. Proper safety equipment helps prevent injuries and ensures compliance with safety regulations. Never underestimate the importance of proper safety equipment when working with machinery. Always use the correct safety equipment for each task to minimize risks. Proper safety equipment is your first line of defense against accidents. Always prioritize safety by using the right gear. Proper use of safety equipment ensures a safe working environment. Never skip safety protocols when using safety equipment. Always follow the manual’s instructions for proper safety equipment usage. Proper safety equipment is vital for protecting yourself and others during repairs. Always use safety equipment as recommended by the manufacturer. Proper safety equipment helps ensure a safe and efficient repair process. Always stay prepared with the right safety gear. Proper use of safety equipment is essential for maintaining safety standards. Always use safety equipment correctly to avoid accidents. Proper safety equipment is a critical part of safe repairs. Always follow safety guidelines for equipment usage. Proper use of safety equipment ensures your safety and the effectiveness of repairs. Always prioritize safety by using the right gear. Proper safety equipment is essential for protecting yourself during repairs. Always use safety equipment as instructed in the manual. Proper safety equipment helps prevent injuries and ensures safe repairs. Always follow safety protocols when using safety equipment. Proper use of safety equipment is crucial for a safe working environment. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the success of repairs. Always stay safe by using the right equipment. Proper use of safety equipment is vital for safe repairs. Always follow the manual’s safety equipment recommendations. Proper safety equipment protects you and ensures compliance with safety standards. Always use safety equipment correctly to minimize risks. Proper safety equipment is essential for safe and effective repairs. Always prioritize safety by using the right gear. Proper use of safety equipment ensures a safe and successful repair process. Always follow the manual’s guidelines for safety equipment usage. Proper safety equipment helps prevent accidents and injuries. Always use safety equipment as recommended by the manufacturer. Proper safety equipment is critical for safe repairs. Always stay prepared with the right safety gear. Proper use of safety equipment ensures your safety and the effectiveness of repairs. Always follow safety protocols when using safety equipment. Proper safety equipment is essential for maintaining safety standards. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the success of repairs. Always prioritize safety by using the right equipment. Proper use of safety equipment is vital for safe repairs. Always follow the manual’s instructions for safety equipment usage. Proper safety equipment helps protect you and others during repairs. Always use safety equipment correctly to avoid accidents. Proper safety equipment is crucial for a safe working environment. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the effectiveness of repairs. Always follow safety guidelines for equipment usage. Proper use of safety equipment is essential for safe repairs. Always prioritize safety by using the right gear. Proper safety equipment is vital for protecting yourself during repairs. Always use safety equipment as instructed in the manual. Proper safety equipment helps prevent injuries and ensures safe repairs. Always follow safety protocols when using safety equipment. Proper use of safety equipment is crucial for a safe working environment. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the success of repairs. Always stay safe by using the right equipment. Proper use of safety equipment is vital for safe repairs. Always follow the manual’s safety equipment recommendations. Proper safety equipment protects you and ensures compliance with safety standards. Always use safety equipment correctly to minimize risks. Proper safety equipment is essential for safe and effective repairs. Always prioritize safety by using the right gear. Proper use of safety equipment ensures a safe and successful repair process. Always follow the manual’s guidelines for safety equipment usage. Proper safety equipment helps prevent accidents and injuries. Always use safety equipment as recommended by the manufacturer. Proper safety equipment is critical for safe repairs. Always stay prepared with the right safety gear. Proper use of safety equipment ensures your safety and the effectiveness of repairs. Always follow safety protocols when using safety equipment. Proper safety equipment is essential for maintaining safety standards. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the success of repairs. Always prioritize safety by using the right equipment. Proper use of safety equipment is vital for safe repairs. Always follow the manual’s instructions for safety equipment usage. Proper safety equipment helps protect you and others during repairs; Always use safety equipment correctly to avoid accidents. Proper safety equipment is crucial for a safe working environment. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the effectiveness of repairs. Always follow safety guidelines for equipment usage. Proper use of safety equipment is essential for safe repairs. Always prioritize safety by using the right gear. Proper safety equipment is vital for protecting yourself during repairs. Always use safety equipment as instructed in the manual. Proper safety equipment helps prevent injuries and ensures safe repairs. Always follow safety protocols when using safety equipment. Proper use of safety equipment is crucial for a safe working environment. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the success of repairs. Always stay safe by using the right equipment. Proper use of safety equipment is vital for safe repairs. Always follow the manual’s safety equipment recommendations. Proper safety equipment protects you and ensures compliance with safety standards. Always use safety equipment correctly to minimize risks. Proper safety equipment is essential for safe and effective repairs. Always prioritize safety by using the right gear. Proper use of safety equipment ensures a safe and successful repair process. Always follow the manual’s guidelines for safety equipment usage. Proper safety equipment helps prevent accidents and injuries. Always use safety equipment as recommended by the manufacturer. Proper safety equipment is critical for safe repairs. Always stay prepared with the right safety gear. Proper use of safety equipment ensures your safety and the effectiveness of repairs. Always follow safety protocols when using safety equipment. Proper safety equipment is essential for maintaining safety standards. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the success of repairs. Always prioritize safety by using the right equipment. Proper use of safety equipment is vital for safe repairs. Always follow the manual’s instructions for safety equipment usage. Proper safety equipment helps protect you and others during repairs. Always use safety equipment correctly to avoid accidents. Proper safety equipment is crucial for a safe working environment. Always use the correct safety gear for each task. Proper safety equipment ensures your safety and the effectiveness of repairs. Always follow safety guidelines for equipment